TPM Audit by JPIM Associates

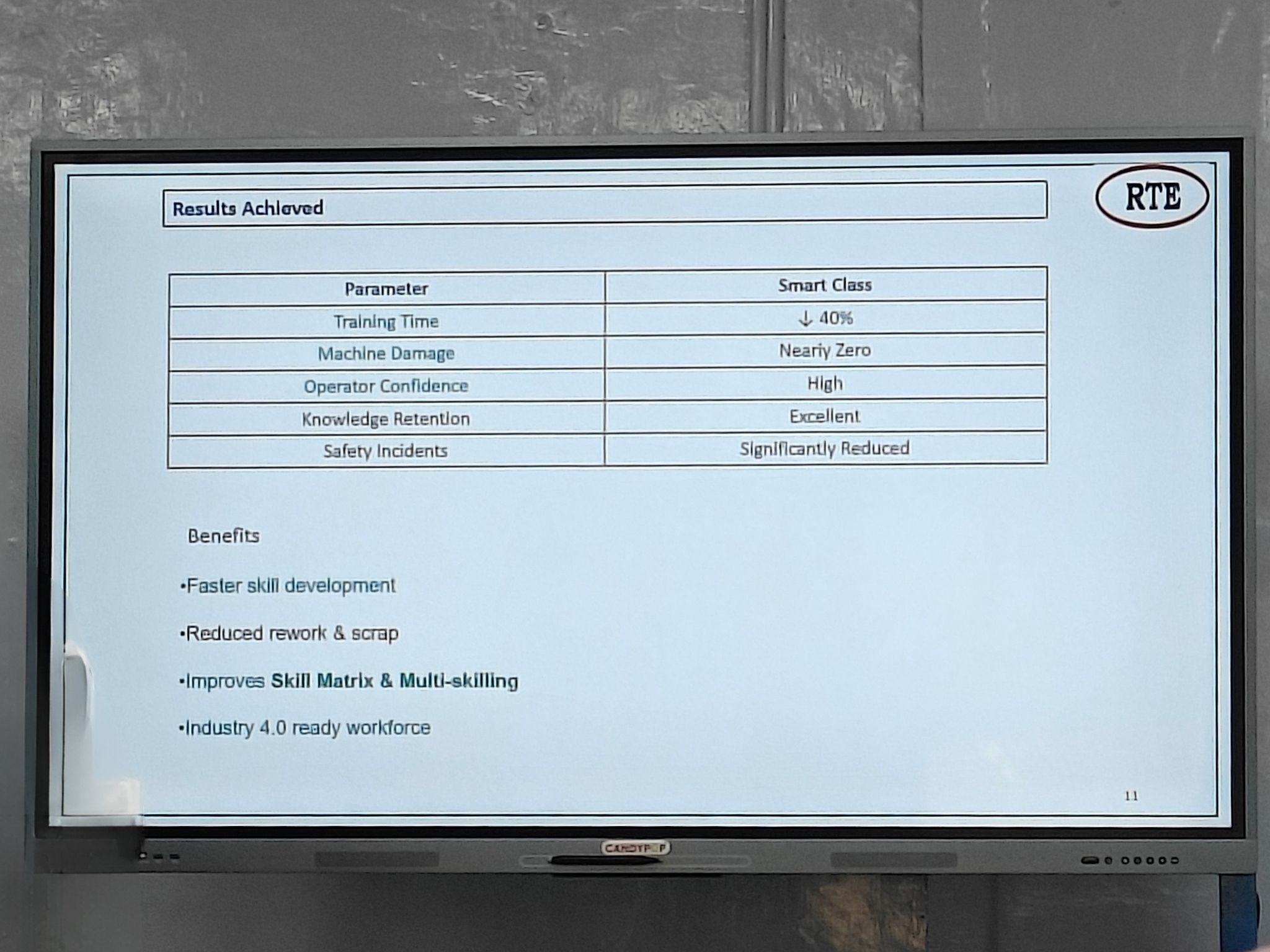

The implementation was rigorously audited by International Japanese Auditors. The VR solution was cited as a key enabler for "Autonomous Maintenance" and "Skills Development".

Audit Gallery

Swipe to view audit session photos